To celebrate the anniversary of the iconic Nike Air Max Classic BW, the brand sought to merge the past with the future in a relevant and thought-provoking way. To do this, they teamed up with local, innovative 3D printing farm Red Cup Village to create a one-of-a-kind, collectable replica of the famed sneaker, which will be available with the first 15 purchases at Jack Lemkus in Cape Town.

Originally known as the Air Max IV, the Air Max BW was first released in 1991 and represented Nike Running’s transition into the 90s. One of the most iconic features of the shoe was its ‘sharply angled’ line, implying speed, agility and cutting-edge design. However, it’s the ‘Big Window’ Nike Air cushioning, from which it gets its name, that is its most recognisable silhouette.

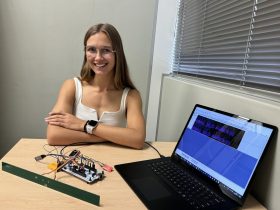

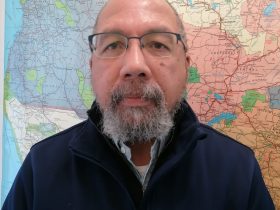

In addition to celebrating the sneaker’s historical anniversary, Luvuyo Ndiki, Managing Director of Red Cup Village, highlights the opportunity to showcase the incredible production capabilities of 3D printing and introduce a new age of manufacturing for South African brands. “We can manufacture everything locally by using 3D scanning technology to reverse engineer any products.”

He continues, “The product was produced in PLA material, which is derived from sugarcane and cornstarch. Both of these are compostable and recyclable, which perfectly aligns with Nike’s sustainable goals to use more environmentally-friendly materials.”

Reducing environmental footprint

As part of Nike’s Move to Zero campaign, 78% of all Nike, Jordan and Converse products contain some recycled material. However, the brand aims to increase that number as adjusted materials, which make up about 70% of Nike’s total carbon footprint, is one of their biggest opportunities to reduce their impact on the environment.

Therefore, joining forces with Red Cup Village, the biggest 3D farm in the southern hemisphere with 125 machines, was an obvious and exciting prospect. “As a leader in recycling plastics into biodegradable 3D prints, we are paving the way for sustainable partnerships going forward. What’s even more exciting is our recently purchased 130 cameras, which allows customers to watch their prints while it’s being made. This adds an interactive element to the experience as customers can see exactly how their product is being made.”

Through Red Cup Village, world-class 3D printing and scanning are being made accessible to individuals, organisations and start-ups across various sectors through innovative concepts and premium products. “With our 3D printing technology, we can increase our turnaround time from two years to just a few hours.”

“Nowadays, consumers want products that work well, and they want them now, and it’s up to manufacturers to meet these demands. Whatever concept you are currently developing and producing – Red Cup Village can supply an appearance model with identical ‘look-and-feel’ characteristics and functions to your final production part. This is what we’ve done with Nike, and we’re excited to use this opportunity to create awareness of the incredible power of 3D printing,” concludes Ndiki.

Leave a Reply