With its industrial manufacturing sector contributing significantly to economic growth and the country’s GDP, South Africa is a prime manufacturing hub on the African continent.

This is according to PwC’s report “Building Avenues for Tomorrow’s Industrial Manufacturing Workforce, Today” which also states that around 1.5 million people ply their trade in industrial manufacturing and are witnessing progression at a rapid pace within the sector.

According to Dennis Phillips, National Sales Manager at abrasive manufacturer, PFERD-South Africa, “The fact that global automaker, Stellantis, well-known for brands such as Fiat, Peugeot, Citroën, Opel, Chrysler and Jeep, will start construction of its automotive manufacturing plant in Gqeberha, Eastern Cape in May of this year, affirms that SA is indeed a popular manufacturing destination”.

That said, the manufacturing industry is ever-evolving which includes its factories and the employees who operate them. Top-of-mind topics include Sustainability, Digital transformation, Automation, Additive Manufacturing and Employee Reskilling.

Sustainability

Phillips explains that sustainability in business has evolved from being a mere buzzword to a fundamental strategic imperative. The industry must embrace sustainable business practices to benefit the company and its broader community. Companies need to integrate sustainable practices into their operations to address environmental and social challenges while driving long-term profitability.

“We need to consider all aspects of business to enable a more sustainable future by re-evaluating how we operate. By producing less waste, recycling the waste we do produce and utilising resources more efficiently, we can all commit to limiting our impact on the environment. Embracing sustainability not only enhances brand reputation and stakeholder trust but also mitigates risks associated with resource scarcity. It accelerates innovation, prompting businesses to develop eco-friendly products and services that meet the needs of a conscious consumer base”, says Phillips.

PFERD products prioritise sustainability through PFERDVALUE, a dual strategy aimed at promoting worker well-being and resource efficiency. PFERDERGONOMICS focuses on improving operator health by reducing the amount of noise, vibration and dust by the abrasive consumable, ultimately enhancing comfort and safety. Meanwhile, PFERDEFFICIENCY ensures their products use less energy, save time and minimise waste while maintaining optimal performance.

The Industrial IoT

As part of a broader digital transformation strategy, companies have the opportunity to reimagine their utilisation of technology, personnel and procedures to propel their business into new realms.

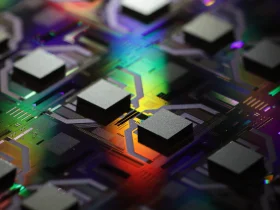

The Industrial Internet of Things (IIoT) involves the integration of smart sensors, actuators and RFID tags (among other technologies) to enhance manufacturing and industrial processes. These interconnected devices enable the collection, exchange and analysis of data, thereby optimising operations and improving overall efficiency.

In various industries, companies leverage industrial robots and automation to produce goods. By integrating IIoT solutions, they can proactively maintain their systems and identify issues before they disrupt the manufacturing process.

Robotics and Automation

Robotics and automation have revolutionised the manufacturing industry, driving efficiency, precision and productivity. Through the deployment of robotic systems and automated technologies, manufacturers can streamline production processes, optimise workflows and enhance overall operational performance.

These technologies enable tasks ranging from repetitive assembly tasks to complex machining as well as dangerous tasks to be executed with accuracy and speed while increasing output consistency. Additionally, robotics and automation facilitate the integration of data analytics and artificial intelligence, enabling predictive maintenance and real-time decision-making for improved resource allocation and cost management.

As a result, companies can stay competitive in a rapidly evolving global market, meeting customer demands for quality, customisation and speed while driving innovation and sustainable growth within the industrial manufacturing sector.

Phillips notes that although Robotics and Automation are nothing new, the adoption rates of this cutting-edge technology are rising. “At PFERD we’ve experienced a significant increase in Robotic System Integrators requesting application-based solutions where their customers are deploying Industrial Robot cells within their manufacturing facilities”. Globally, PFERD’s expertise and experienced Application Specialists have successfully optimised numerous robotic applications that subsequently made significant improvements to their customers’ operational efficiency.

Additive Manufacturing: Exciting Opportunities Await

The utilisation of additive layer manufacturing, commonly known as 3D printing, presents a significant opportunity for manufacturers in South Africa. This technology offers numerous advantages for large-scale production, including rapid prototyping, cost efficiency, customisation of components and shortened lead times.

According to Phillips, there are currently multiple ongoing 3D printing initiatives, such as a proof-of-concept project aimed at constructing affordable housing. “In the metalworking sector, customers utilise 3D printing to produce medical implants and aviation parts, where after they use our abrasives to achieve the correct surface finish and geometries—a critical requirement given the final product’s intended use”. Furthermore, manufacturers are leveraging 3D printers to fabricate parts for the automotive and power generation industries, showcasing the versatility and potential of this innovative manufacturing technique.

Employee Reskilling for Work of the Future

Employee turnover is a big concern for companies because it’s time-consuming and expensive; even more so in the context of smart factories—facilities where 4IR technology is deployed—because of the time it takes the new employee to reach the same level of productivity as the person they replaced.

Therefore, companies, as stated in The World Economic Forum’s World of Work Report, are prioritising training their employees to use AI, big data as well as developing their analytical and creative thinking skills.

A study by the Manufacturing Institute’s Center for Manufacturing Research looked at the factors that affect retention and a key finding among employees under the age of 30 was that they stay with their current employer due to the company’s training and reskilling programme that allows them to further their careers.

At PFERD, we’ve come up with various ways to continually train and upskill our staff. Furthermore, we also onboard innovative ways, through our Training Academy, to continue assisting our customers in training and upskilling their staff regarding new ways of using abrasives effectively within their processes.

To remain globally competitive, it’s critically important that South Africa upskill its workforce to ensure competitiveness and to help the country continue to attract foreign direct investment”, explains Phillips.

Leave a Reply